Understanding the electrical heart of your material handling equipment is crucial for efficient operation and timely repairs. This is where the Toyota Forklift Alternator Wiring Diagram becomes an indispensable tool. Whether you're a seasoned mechanic or a forklift owner looking to troubleshoot, deciphering this diagram is key to ensuring your forklift's battery stays charged and ready for action.

Decoding the Electrical Blueprint The Toyota Forklift Alternator Wiring Diagram

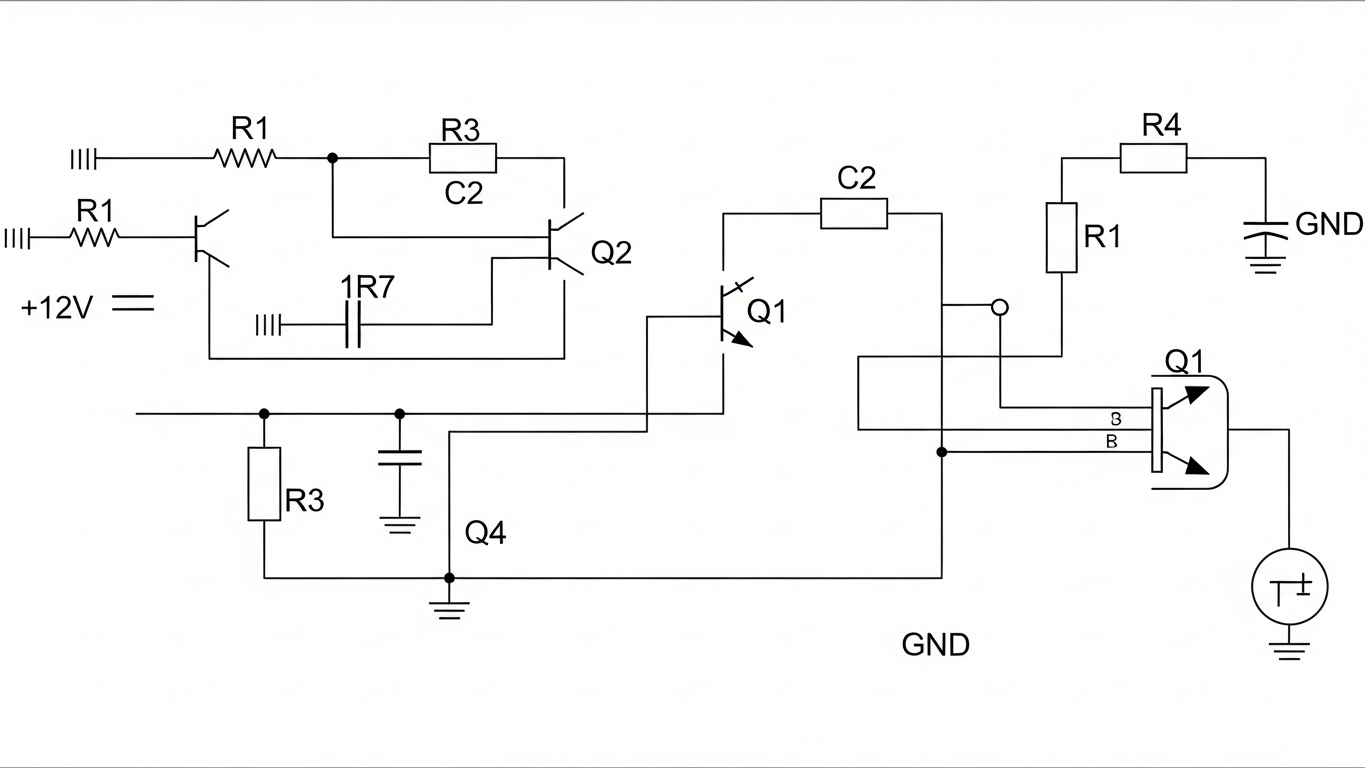

A Toyota Forklift Alternator Wiring Diagram is essentially a visual roadmap that illustrates how the alternator, battery, voltage regulator, and other related electrical components are connected within your forklift. It's a technical drawing that uses standardized symbols to represent different parts and lines to show the flow of electrical current. Think of it as the blueprint for the charging system, detailing every wire, connector, and terminal. This allows for precise identification of components and understanding their interrelationships. The diagram is vital for diagnosing charging issues, replacing faulty parts, or even performing preventative maintenance on the electrical system.

The primary function of the alternator is to generate electricity to recharge the forklift's battery while the engine is running and to supply power to the forklift's electrical systems. The Toyota Forklift Alternator Wiring Diagram shows how the alternator's output is routed to the battery and how the voltage regulator monitors and controls the charging voltage. Without a properly functioning alternator, your forklift's battery will eventually drain, leaving you with an inoperable machine. The importance of having a clear and accurate Toyota Forklift Alternator Wiring Diagram cannot be overstated for maintaining optimal performance and minimizing downtime. Here are some key elements you'll typically find:

- Alternator Output Terminal

- Battery Positive Terminal

- Voltage Regulator Connections

- Ground Connections

- Ignition Switch Connection

| Component | Function |

|---|---|

| Alternator | Generates electrical power |

| Voltage Regulator | Controls charging voltage |

| Battery | Stores electrical energy |

The diagram also helps in understanding the charging circuit's path. When the engine starts, the alternator begins to spin, producing AC voltage. This AC voltage is then converted to DC voltage by internal diodes. The voltage regulator then ensures this DC voltage is within the optimal range for charging the battery, typically between 13.5 and 14.5 volts for a 12-volt system. If the voltage is too high, it can damage the battery; if it's too low, the battery won't charge effectively. The Toyota Forklift Alternator Wiring Diagram provides the specific connection points for these critical functions, enabling technicians to quickly pinpoint where a problem might lie. For instance, a break in the wire from the alternator to the regulator, or a faulty regulator itself, will be clearly indicated on the diagram.

For a comprehensive understanding and practical application of this vital information, we highly recommend referring to the official Toyota Forklift Alternator Wiring Diagram specific to your forklift model. This resource will provide the most accurate and detailed schematics for your equipment.